|

This

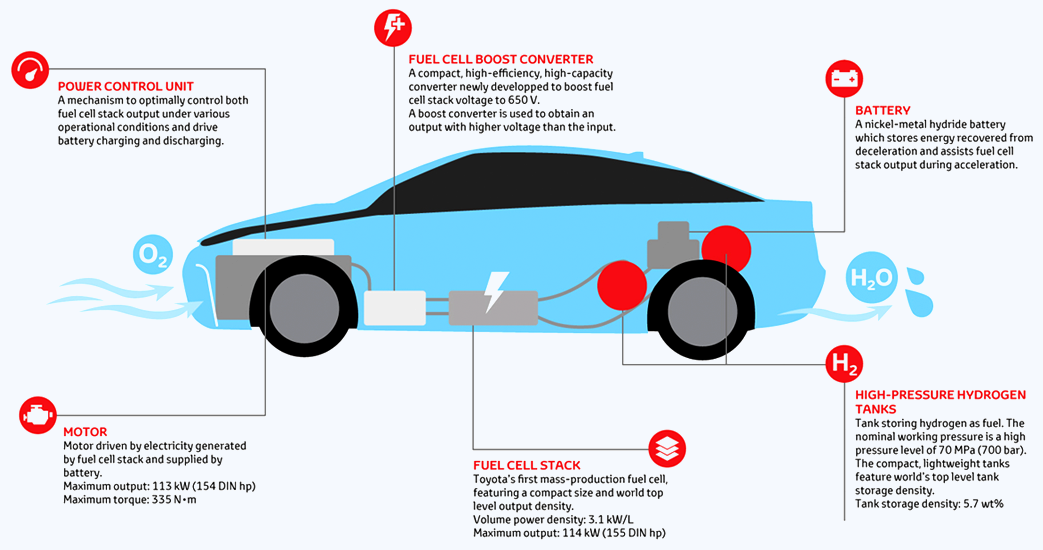

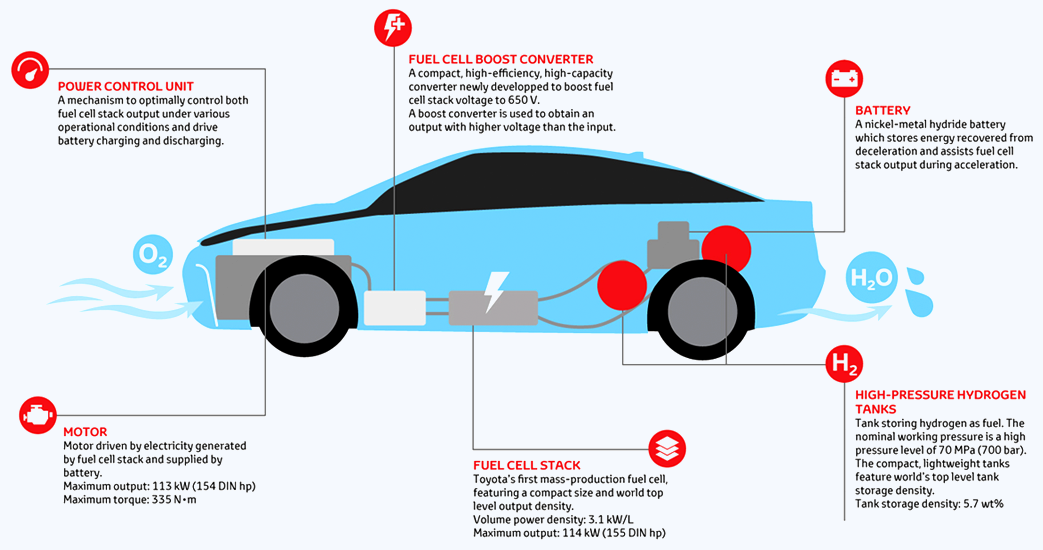

infographic outlines the components of a popular FCEV design, explaining in

brief what part each bit of tech plays in the drivetrain, from hydrogen

storage, through power electronics, to re-combining the oxygen from air with

hydrogen to give us electricity and water. The only thing stopping FCEVs

from being fully exploited in the quest for zero emission mobility, is the

lack of and confused state of EV infrastructure

generally.

FCEV stands for

Fuel Cell Electric Vehicle. FCEVs are a type of vehicle that use compressed hydrogen gas as fuel to generate electric power via a highly efficient energy converter, a fuel cell. The fuel cell transforms the hydrogen directly into electricity to power an electric

motor.

The FCEVs currently being prepared for commercialisation have a driving range comparable to petrol and diesel vehicles, typically between 385 and 700 km (240 and 435 miles) on a full tank.

Industrial gas companies have developed hydrogen fuel dispensing systems that are safe and simple to use. International standards ensure compatibility between refuelling stations and vehicles, and the refuelling process takes around 3 to 5 minutes offering refuelling times similar to those of conventional

petrol or

diesel cars.

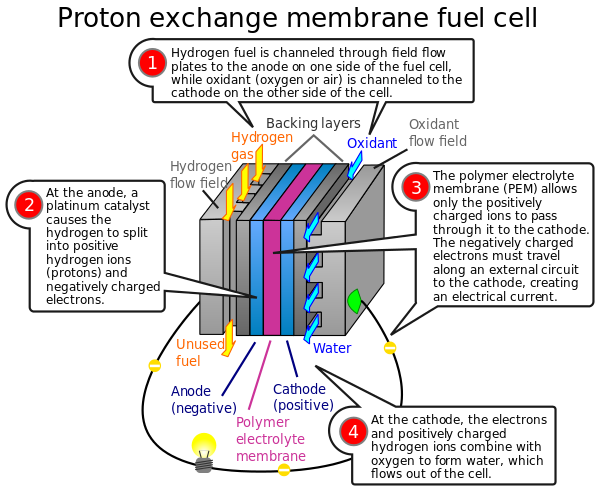

Fuel cells in vehicles generate electricity generally using oxygen from the

air and compressed hydrogen. Most fuel cell vehicles are classified as zero-emissions vehicles that emit only water and heat. As compared with internal combustion vehicles, hydrogen vehicles centralize pollutants at the site of the hydrogen production, where hydrogen is typically derived from reformed natural gas. Transporting and storing hydrogen may also create pollutants.

THE NEXT GREEN CAR 21 APRIL 2021

Driving a fuel cell car is a breeze. As with any all-electric or automatic transmission vehicle, there are no gears to worry about, the main decision being the level or strength of regenerative braking required. Since FCEVs are electric vehicles, power is available instantly as all mass production models include a battery as part of the power-train. This is to act as a buffer and provide instant power from the electric motor, instead of having to wait for the fuel cell to kick in and provide an electric charge on demand.

However, ownership is not all plain sailing. The current hydrogen refuelling infrastructure (or lack of it) is the biggest constraint with less than half a dozen publicly available refilling stations currently in the UK. The technology is more restrictive than buying a battery electric car since at least most people have access to a home-based socket with which to charge their EV. Given that very few households have a hydrogen refuelling unit in their garage, living within a convenient distance of a public hydrogen refuelling station is essential.

Apart from the lack of locations, refuelling a FCEV is almost as simple and quick as using a petrol pump, and anyone who has used an LPG vehicle will find plenty of similarities. The driver fixes the refuelling station's nozzle to the car and locks it in place creating a sealed system. The pump will then check the seal can withstand the pressure by pre-conditioning it, before proceeding to dispense the hydrogen at the industry standard 70 MPa (10,000 psi) if all is ok.

Using a state-of-the-art 70 MPa refuelling dispenser, a few minutes refuel will provide most FCEVs with around 300 of range miles - as opposed to the half an hour rapid charge for a battery electric car offering around 100 miles of driving. Look out for older 35 MPa units however, as these will only provide a half-fill, so limiting driving range. Once completed, the user simply unlocks the nozzle and replaces it at the pump before driving off on hydrogen fuel cell electric power with zero harmful emissions.

For those who are tempted by fuel cell technology, only a few models are commercially available. Unfortunately, these remain expensive compared to similarly sized petrol, diesel or even battery electric rivals. Toyota's Mirai, for example, costs around £60,000 with Toyota expected to lose money on every one sold. This price includes the £4,500 Category 1 UK Plug-in Car Grant (PiCG) which includes the Mirai as an eligible vehicle.

In the UK, it isn't yet possible to buy a FCEV outright; Hyundai and Toyota only offer cars on lease. While this is mainly due to the limited refuelling infrastructure, it also protects owners from any technical and durability issues associated with a new technology.

Hydrogen is sold in kilograms rather than volume (litres or gallons), and current prices are around £10 to £15 per kg. As the Mirai's tank holds approximately 5 kg, a full hydrogen refill would cost between £50 and £75 meaning that hydrogen FCEVS are more expensive per distance able to travel than both internal combustion vehicles and BEVs. With increased hydrogen use though, costs are likely to come down in the future. Manufacturers are removing this problem though by incorporating fuel costs into the cost of the lease. Therefore, you won't need to pay anything 'at the pump' and the entire motoring costs are paid in one lump sum each month.

The rest of the car's running costs again bear a close resemblance to BEVs: servicing costs are significantly less than an internal combustion car because of reduced numbers of moving parts, while consumables such as brake pads are used less because of brake energy recuperation. FCEVs are also exempt from the London Congestion Charging Zone and, with no CO2 emissions, are exempt from paying Vehicle Excise Duty (VED or road tax). By Chris Lilly

FUEL CELLS RANGE EXTENDED

VANS

Symbio designs hydrogen fuel

cell kits that can be incorporated into various different types of electric vehicles (utility vehicles, vans, buses, heavy-goods vehicles, boats, etc.) and are associated with a range of digital services (vehicle repairs, remote fleet management, etc.). Once equipped in this way, these vehicles provide enhanced ease of use (full in three minutes, autonomy twice that of their battery equivalents, etc.) while remaining “zero emissions”. There are several hundred of these vehicles – for the most part, light utility vehicles such as the Kangoo ZE H2) – on the roads in France and across Europe. Founded in 2010, the CEA, ENGIE and Michelin all own a stake in

Symbio.

IN THE US

FCEVs and the hydrogen infrastructure to fuel them are in the early stages of implementation. The U.S. Department of Energy leads research efforts to make hydrogen-powered vehicles an affordable, environmentally friendly, and safe transportation option.

Hydrogen is considered an alternative fuel under the Energy Policy Act of 1992 and qualifies for alternative fuel vehicle tax credits.

More hydrogen stations are planned, particularly in California, where, as of 2019, according to Hydrogen View, there had been over 7,500 FCEVs sold or leased. Critics doubt whether hydrogen will be efficient or cost-effective for automobiles, as compared with other zero emission technologies, and in 2019, USA Today stated "what is tough to dispute is that the hydrogen fuel cell dream is all but dead for the passenger vehicle market."

As of July 2020, there were 43 publicly accessible hydrogen refueling stations in the US, 41 of which were located in California. In 2013, Governor Jerry Brown signed AB 8, a bill to fund $20 million a year for 10 years to build up to 100 stations. In 2014, the California Energy Commission funded $46.6 million to build 28 stations.

JAPAN

Japan got its first commercial hydrogen fueling station in 2014. By March 2016, Japan had 80 hydrogen fueling stations, and the Japanese government aims to double this number to 160 by 2020. In May 2017, there were 91 hydrogen fueling stations in Japan. Germany had 18 public hydrogen fueling stations in July 2015. The German government hoped to increase this number to 50 by end of 2016, but only 30 were open in June 2017.

FUEL CELL ELECTRIC CARS

The Daimler GLC F-CELL is set to combine innovative fuel-cell and battery technology in the form of a plug-in hybrid: in addition to hydrogen it will also run on electricity. With 4.4 kg of hydrogen on board, the preproduction model produces enough energy for a range of up to 437* km in the

NEDC. F-CELL drivers will also benefit from a range of up to 49 km in the NEDC thanks to the large lithium-ion battery and its output of 147 kW.

The Toyota Mirai (which means ‘future’ in Japanese) signals the start of a new age of vehicles. Using hydrogen – an important future energy carrier – as fuel to generate electricity, the Mirai achieves superior environmental performance with the convenience and driving pleasure expected of any car. The Mirai is fitted with two 700 bar hydrogen tanks enough to provide a driving range of 500 km. It is the first mass produced sedan fuel cell vehicle with excellent performance of 113 kW and a low centre of gravity.

The Honda Clarity Fuel Cell houses an advanced Honda built fuel cell stack in the engine compartment. As a result, the Honda Clarity Fuel Cell sedan is capable of seating five occupants. Its powertain delivers 130 kW and 300 Nm maximum torque. The Clarity Fuel Cell offers a generous range of 650 km

(NEDC) with hydrogen stored at 700 bar. The FCX Clarity concept car was introduced in 2008 for leasing by customers in Japan and Southern California and discontinued by 2015. From 2008 to 2014, Honda leased a total of 45 FCX units in the US. Over 20 other FCEVs prototypes and demonstration cars were released in that time period, including the GM HydroGen4, and Mercedes-Benz

F-Cell.

Retail deliveries of the 2017 Honda Clarity Fuel Cell began in California in December 2016. The 2017 Clarity has the highest combined and city fuel economy ratings among all hydrogen fuel cell cars rated by the EPA, with a combined city/highway rating of 67 miles per gallon gasoline equivalent

(MPGe), and 68 MPGe in city driving. In 2019, Katsushi Inoue, the president of

Honda Europe, stated, "Our focus is on hybrid and electric vehicles now. Maybe hydrogen fuel cell cars will come, but that’s a technology for the next era."

The B-Class F-Cell (Daimler) vehicles are fitted with a 700-bar hydrogen tank in the sandwich floor unit. Its electric motor develops an output of 100 kW, with a torque of 290 Nm, and thus has the power rating of a

two-litre gasoline engine. The zero-emission drive system consumes the equivalent of 3.3 litres of diesel per 100 kilometres

(NEDC).

The Hyundai ix35 FCEV Fuel Cell vehicle has been available for lease since 2014, when 54 units were leased.

Sales of the Toyota Mirai to government and corporate customers began in Japan in December 2014. Pricing started at ¥6,700,000 (~US$57,400) before taxes and a government incentive of ¥2,000,000 (~US$19,600). Former European Parliament President Pat Cox estimated that Toyota initially would lose about $100,000 on each Mirai sold. As of December 2017, global sales totaled 5,300 Mirais. The top selling markets were the U.S. with 2,900 units, Japan with 2,100 and Europe with 200.

By 2017, Daimler phased out its FCEV development, citing declining battery costs and increasing range of EVs, and most of the automobile companies developing hydrogen cars had switched their focus to battery

electric

vehicles.

BUSES

There are also demonstration models of buses, and in 2011 there were over 100 fuel cell buses deployed around the world. Most of these buses were produced by UTC Power, Toyota, Ballard, Hydrogenics, and Proton Motor. UTC buses had accumulated over 970,000 km (600,000 mi) of driving. Fuel cell buses have a 30-141% higher fuel economy than diesel buses and natural gas buses. Fuel cell buses have been deployed in cities around the world, although a Whistler, British Columbia project was discontinued in 2015. The Fuel Cell Bus Club is a global cooperative effort in trial fuel cell buses. Notable projects include:

- 12 Fuel cell buses were deployed in the Oakland and San Francisco Bay area of California.

- Daimler AG, with thirty-six experimental buses powered by Ballard Power Systems fuel cells, completed a successful three-year trial, in eleven cities, in 2007.

- A fleet of Thor buses with UTC Power fuel cells was deployed in California, operated by SunLine Transit Agency.

- The first hydrogen fuel cell bus prototype in Brazil was deployed in São Paulo. The bus was manufactured in Caxias do Sul, and the hydrogen fuel was to be produced in São Bernardo do Campo from water through electrolysis. The program, called "Ônibus Brasileiro a Hidrogênio" (Brazilian Hydrogen Autobus), included three buses.

TRUCKS

In 2020, Hyundai started to manufacture hydrogen powered 34-ton cargo trucks under the model name XCIENT, making an initial shipment of 10 of the vehicles to Switzerland. They are able to travel 400 kilometres (250 mi) on a full tank and they take 8 to 20 minutes to fill up.

In 2020, Daimler announced the Mercedes-Benz GenH2 liquid hydrogen concept expected to be produced beginning in 2023.

ENVIRONMENTAL IMPACT

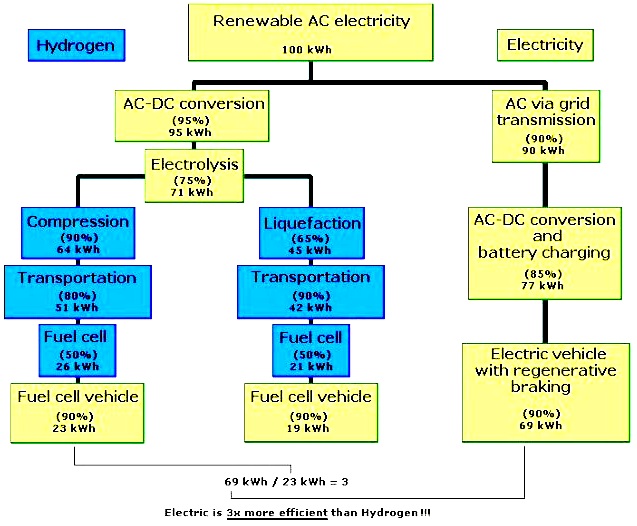

The environmental impact of fuel cell vehicles depends on the primary energy with which the hydrogen was produced. Fuel cell vehicles are only environmentally benign when the hydrogen was produced with renewable energy. If this is the case fuel cell cars are cleaner and more efficient than fossil fuel cars. They are not as efficient as battery electric vehicles which consume much less energy in the conversion chain. Usually a fuel cell car consumes 2.4 times more energy than a battery electric car, because electrolysis and storage of hydrogen is much less efficient than using electricity to directly load a battery.

As of 2009, motor vehicles used most of the petroleum consumed in the U.S. and produced over 60% of the carbon monoxide emissions and about 20% of greenhouse gas emissions in the United States, however production of hydrogen for hydro cracking used in gasoline production chief amongst its industrial uses was responsible for approximately 10% of fleet wide greenhouse gas emissions. In contrast, a vehicle fueled with pure hydrogen emits few pollutants, producing mainly

water and heat, although the production of the hydrogen would create pollutants unless the hydrogen used in the fuel cell were produced using only renewable energy.

In a 2005 Well-to-Wheels analysis, the DOE estimated that fuel cell electric vehicles using hydrogen produced from natural gas would result in emissions of approximately 55% of the CO2 per mile of internal combustion engine vehicles and have approximately 25% less emissions than hybrid vehicles. In 2006, Ulf Bossel stated that the large amount of energy required to isolate hydrogen from natural compounds (water, natural gas, biomass), package the light gas by compression or liquefaction, transfer the energy carrier to the user, plus the energy lost when it is converted to useful electricity with fuel cells, leaves around 25% for practical use." Richard Gilbert, co-author of Transport Revolutions: Moving People and Freight without Oil (2010), comments similarly, that producing hydrogen gas ends up using some of the energy it creates. Then, energy is taken up by converting the hydrogen back into electricity within fuel cells. "'This means that only a quarter of the initially available energy reaches the electric motor' ... Such losses in conversion don't stack up well against, for instance, recharging an electric vehicle (EV) like the Nissan Leaf or Chevy Volt from a wall socket".

A 2010 Well-to-wheels analysis of hydrogen fuel cell vehicles report from Argonne National Laboratory states that renewable H2 pathways offer much larger green house gas benefits. This result has recently been confirmed. In 2010, a US DOE Well-to-Wheels publication assumed that the efficiency of the single step of compressing hydrogen to 6,250 psi (43.1 MPa) at the refueling station is 94%. A 2016 study in the November issue of the journal Energy by scientists at Stanford University and the Technical University of Munich concluded that, even assuming local hydrogen production,"investing in all-electric battery vehicles is a more economical choice for reducing

carbon dioxide emissions, primarily due to their lower cost and significantly higher energy efficiency."

CRITICISM

In 2008, professor Jeremy P. Meyers, in the Electrochemical Society journal Interface wrote, "While fuel cells are efficient relative to combustion engines, they are not as efficient as batteries, due primarily to the inefficiency of the oxygen reduction reaction. ... They make the most sense for operation disconnected from the grid, or when fuel can be provided continuously. For applications that require frequent and relatively rapid start-ups ... where zero emissions are a requirement, as in enclosed spaces such as warehouses, and where hydrogen is considered an acceptable reactant, a [PEM fuel cell] is becoming an increasingly attractive choice [if exchanging batteries is inconvenient]". The practical cost of fuel cells for cars will remain high, however, until production volumes incorporate economies of scale and a well-developed supply chain. Until then, costs are roughly one order of magnitude higher than DOE targets.

Also in 2008, Wired News reported that "experts say it will be 40 years or more before hydrogen has any meaningful impact on gasoline consumption or global warming, and we can't afford to wait that long. In the meantime, fuel cells are diverting resources from more immediate

solutions." The Economist magazine, in 2008, quoted Robert Zubrin, the author of Energy Victory, as saying: "Hydrogen is 'just about the worst possible vehicle fuel'". The magazine noted that most hydrogen is produced through steam reformation, which creates at least as much emission of carbon per mile as some of today's gasoline cars. On the other hand, if the hydrogen could be produced using renewable energy, "it would surely be easier simply to use this energy to charge the batteries of all-electric or plug-in hybrid vehicles." The Los Angeles Times wrote in 2009, "Any way you look at it, hydrogen is a lousy way to move cars." The Washington Post asked in November 2009, "[W]hy would you want to store energy in the form of hydrogen and then use that hydrogen to produce electricity for a motor, when

electrical energy is already waiting to be sucked out of sockets all over America and stored in auto batteries...?"

The Motley Fool stated in 2013 that "there are still cost-prohibitive obstacles [for hydrogen cars] relating to transportation, storage, and, most importantly, production." Volkswagen's Rudolf Krebs said in 2013 that "no matter how excellent you make the cars themselves, the laws of physics hinder their overall efficiency. The most efficient way to convert energy to mobility is electricity." He elaborated: "Hydrogen mobility only makes sense if you use green energy", but ... you need to convert it first into hydrogen "with low efficiencies" where "you lose about 40 percent of the initial energy". You then must compress the hydrogen and store it under high pressure in tanks, which uses more energy. "And then you have to convert the hydrogen back to electricity in a fuel cell with another efficiency loss". Krebs continued: "in the end, from your original 100 percent of electric energy, you end up with 30 to 40 percent."

In 2014, electric automotive and energy futurist Julian Cox calculated the emissions produced per EPA combined cycle driven mile, well to wheel, by real-world hydrogen fuel cell vehicles and figures aggregated from the test subjects enrolled in the US DOE's long term NREL FCV study. The report presented official data that refutes marketers' claims of any inherent benefits of hydrogen fuel cells over the drive trains of equivalent conventional gasoline hybrids and even ordinary small-engined cars of equivalent drive train performance due to the emissions intensity of hydrogen production from natural gas. The report demonstrated the economic inevitability of continued methane use in hydrogen production due to the cost tripping effect of hydrogen fuel cells on renewable mileage due to conversion losses of electricity to and from hydrogen when compared to the direct use of electricity in an ordinary electric vehicle.

The analysis contradicts the marketing claims of vehicle manufacturers involved in promoting hydrogen fuel cells. The analysis concluded that public policy in relation to hydrogen fuel cells has been misled by false equivalences to very large, very old or very high powered gasoline vehicles that do not accurately reflect the choices of emissions reduction technologies readily available amongst lower cost and pre-existing newer vehicle choices available to consumers. Cox wrote in 2014 that producing hydrogen from

methane "is significantly more carbon intensive per unit of energy than

coal. Mistaking fossil hydrogen from the hydraulic fracturing of shales for an environmentally sustainable energy pathway threatens to encourage energy policies that will dilute and potentially derail global efforts to head-off climate change due to the risk of diverting investment and focus from vehicle technologies that are economically compatible with renewable energy." The Business Insider commented in 2013:

Pure hydrogen can be industrially derived, but it takes energy. If that energy does not come from renewable sources, then fuel-cell cars are not as clean as they seem. ... Another challenge is the lack of infrastructure. Gas stations need to invest in the ability to refuel hydrogen tanks before FCEVs become practical, and it's unlikely many will do that while there are so few customers on the road today. ... Compounding the lack of infrastructure is the high cost of the technology. Fuel cells are "still very, very expensive".

In 2014, former Dept. of Energy official Joseph Romm wrote three articles stating that FCVs still had not overcome the following issues: high cost of the vehicles, high fueling cost, and a lack of fuel-delivery infrastructure. He stated: "It would take several miracles to overcome all of those problems simultaneously in the coming decades." Moreover, he said, "FCVs aren't green" because of escaping methane during natural gas extraction and during the production of hydrogen, 95% which is produced using the steam reforming process. He concluded that renewable energy cannot economically be used to make hydrogen for an FCV fleet "either now or in the future." GreenTech Media's analyst reached similar conclusions in 2014. In 2015, Clean Technica listed some of the disadvantages of hydrogen fuel cell vehicles as did Car Throttle. Another Clean Technica writer concluded, "while hydrogen may have a part to play in the world of energy storage (especially seasonal storage), it looks like a dead end when it comes to mainstream vehicles."

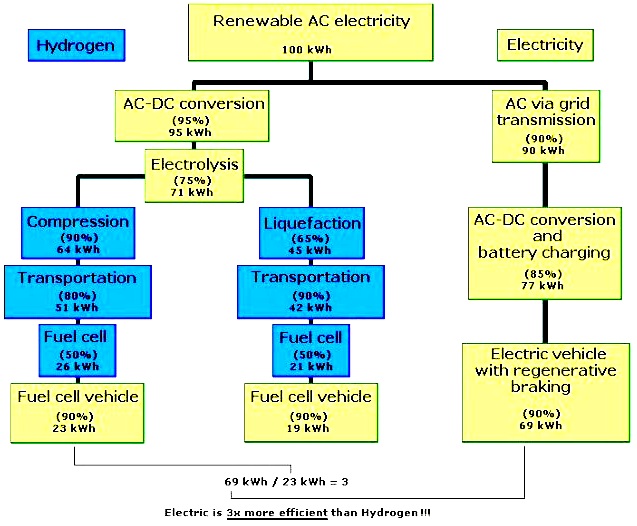

This

infographic reveals the inefficiencies of the hydrogen conversion chain,

that hundreds of researchers are doing their best to overcome with more

efficient electrolyzers. PEM fuel cells are unlikely to get much above 50%

by way of turning hydrogen gas into electricity,

but should there be a breakthrough, that would be a huge bonus.

A 2017 analysis published in Green Car Reports found that the best hydrogen fuel cell vehicles consume "more than three times more electricity per mile than an electric vehicle ... generate more greenhouse-gas emissions than other powertrain technologies ... [and have] very high fuel costs. ... Considering all the obstacles and requirements for new infrastructure (estimated to cost as much as $400 billion), fuel-cell vehicles seem likely to be a niche technology at best, with little impact on U.S. oil consumption. In 2017, Michael Barnard, writing in Forbes, listed the continuing disadvantages of hydrogen fuel cell cars and concluded that "by about 2008, it was very clear that hydrogen was and would be inferior to battery technology as a storage of energy for vehicles. By 2025 the last hold outs should likely be retiring their fuel cell dreams.”

A 2019 video by Real Engineering noted that using hydrogen as a fuel for cars does not help to reduce carbon emissions from transportation. The 95% of hydrogen still produced from fossil fuels releases carbon dioxide, and producing hydrogen from water is an energy-consuming process. Storing hydrogen requires more energy either to cool it down to the liquid state or to put it into tanks under high pressure, and delivering the hydrogen to fueling stations requires more energy and may release more carbon. The hydrogen needed to move a FCV a kilometer costs approximately 8 times as much as the electricity needed to move a BEV the same distance. Also in 2019, Katsushi Inoue, the president of Honda Europe, stated, "Our focus is on hybrid and electric vehicles now. Maybe hydrogen fuel cell cars will come, but that’s a technology for the next era." A 2020 assessment concluded that hydrogen vehicles are still only 38% efficient, while battery EVs are 80% efficient.

FCEVs cannot get away from the poor conversion efficiency, but hydrogen in

(for example)

SmartNet Service Stations, provides a way of storing large amounts of energy, where batteries cannot compete. Especially, for load leveling of

national

grids, so plugging the infrastructure mix that is at the moment chaotic to say the least, so insecure.

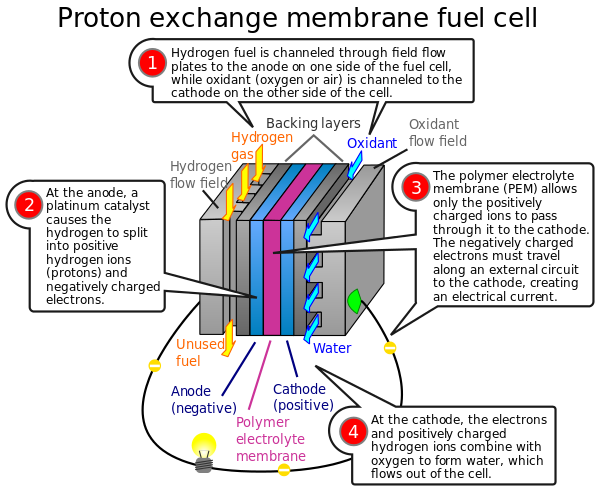

The

most common fuel cell is comprised of a stack of PEM modules.

....

EUROPEAN

EV AUTO MANUFACTURERS:

-

Alfa

Romeo

-

Audi

-

BMW

-

Citroen

-

Fiat

-

Ford

-

Lotus

-

Mercedes

-

Peugeot

-

Renault

-

Seat

-

Smart

-

Volkswagen

MAKES

OF ELECTRIC TRUCKS

-

DAF

-

MAN

-

Mercedes

Benz

-

Renault

-

Volkswagen

-

Volvo

MAKES

OF ELECTRIC BUSES & COACHES

-

BDY

-

ASHOK

LEYLAND

LINKS

& REFERENCE https://h2me.eu/about/fcevs/

https://www.nextgreencar.com/fuelcellcars/ http://www.ukh2mobility.co.uk/fcevs/ https://afdc.energy.gov/vehicles/fuel_cell.html

https://afdc.energy.gov/laws/key_legislation#epact92

Please

use our A-Z

INDEX to navigate this site

This

website is provided on a free basis as a public information service.

copyright © Climate Change Trust 2021. Solar

Studios, BN271RF, United Kingdom.

|